Quality Practices

-

Transports Seed cotton from the market to ginnery by truck to protect it from the sun, rain and dust.

-

We keep the factory premises clean, by providing waste bins and spittoons at different places.

-

Heaps the Seed cotton are kept on a clean paved platforms or in a well-ventilated and covered go downs.

-

Employ extra labours to remove the contaminants while forming Seed cotton heaps.

-

Drying moist Seed cotton in the sun for limiting the moisture content to within 7-9 percent.

-

Provides all the workers with white cotton clothing to wear and caps to cover their heads so that hair may not contaminate the cotton.

-

Handles all the materials such as seed cotton, seed and lint with care to avoid mixing with foreign matters.

-

Using grease instead of oil in gear boxes to prevent contamination with oil

-

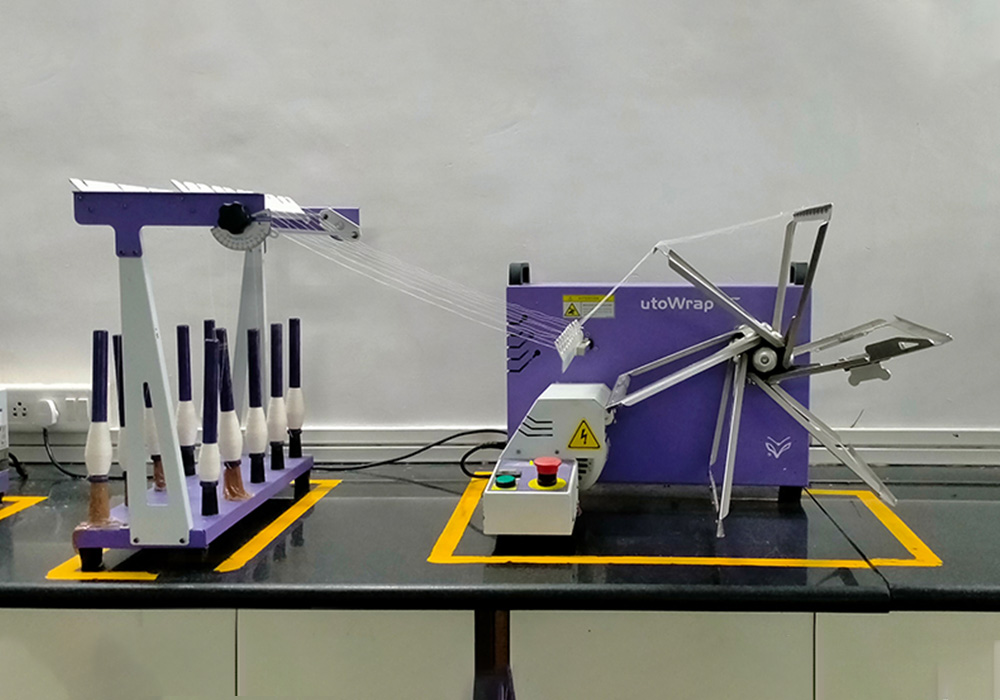

Maintaining proper overlap setting and ensure periodical grooming of leather roller to avoid seed cut and fibre breakage.

-

Removing metal wires, bolts, machine parts, leather pieces, oil spill etc. to prevent their mixing with seed cotton/lint.

-

Before feeding to baling press once again we ensure that no extraneous matter gets into the lint

-

Using new iron straps of 18- 19 gauge and 12.5 mm width for fastening cotton bales

-

Using quick drying good quality ink to print the specifications on the bale cover printed on label made of cotton or plastic.

-

To store the cotton bales in a covered go down to avert their exposure from wind, rain and dust etc.

Our Extra Care

1. Quality Awareness Boards/Displays

At various places to instill quality culture among workers

- In the compound

- In the Gin House

2. Disposal of Trash

Arrangement is made for regular disposal of trash as soon as it accumulates. This is necessary to prevent the mixing of trash with seed cotton/lint.

3. Variety -wise Processing

Variety-wise and grade-wise cotton is heaped and processed.

4. Bale is Covered

On all sides, preferably with cotton cloth and in the manner specified in BIS Standard and export packing.